Making a Material Difference®

Advantages of AKTON viscoelastic polymer

• Excellent shear reducing qualities

• Soft, flexible film

• Enhances patient stability

• Evenly distributes heat and pressure

• Clinically proven to help prevent pressure injuries

• Reusable & Cost Effective

• Does not support bacterial growth

• Hypoallergenic

• Imaging compatible

• Biocompatible

• Not made with natural rubber latex

• Free of phthalates, plasticizers & silicone

• Free of DEHP

Our reusable Overlays are impervious to fluids, will not support bacterial growth, do not leak or flow if punctured, and are easy to clean and maintain.

The shear reducing qualities of the products are enhanced by the combination of the soft, flexible outer film and the tissue equivalent polymer.

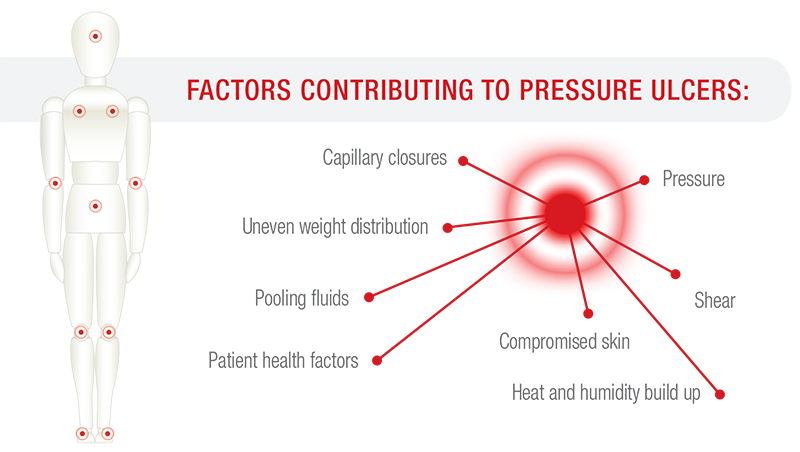

How our proprietary polymer reduces the risk.

The ultrasoft polymer combined with the soft, flexible surface of our pads allows the product to move with the patient, reducing negative effects of shear on fragile skin. In addition, the Akton® polymer distributes weight and dissipates heat; reducing the risk of high-pressure points and hot spot development that can lead to pressure injuries. These benefits combined enhance patient protection.